बà¥à¤®à¥à¤¬à¥ बà¥à¤°à¥à¤¡ मशà¥à¤¨à¥à¤

बà¥à¤®à¥à¤¬à¥ बà¥à¤°à¥à¤¡ मशà¥à¤¨à¥à¤ Specification

- प्रॉडक्ट टाइप

- बैम्बू बोर्ड मशीन

- मशीन का प्रकार

- मशीन स्टाइल

- क्षमता

- 2000-3000 Kg/Day

- वोल्टेज

- 380 V

- पावर

- ऑटोमेशन

- मोटर

- Heavy Duty Electric Motor

- स्पीड

- Variable Speed

- आयाम (एल* डब्ल्यू* एच)

- 4250 x 1400 x 1500 mm

- वज़न

- 2600 kg

- रंग

- Green & White

- Material Processed

- Natural Bamboo

- Raw Material Input

- Bamboo Strips

- Output Board Size

- 2440 x 1220 mm (Standard)

- Control System

- PLC Based Control Panel

- Noise Level

- ≤ 80 dB

- Cooling System

- Integrated Water Cooling

- Applications

- Furniture, Construction, Decorative Panel Manufacturing

- Panel Thickness Range

- 10-50 mm

- Drive System

- Gearbox Drive

- Surface Treatment

- Anti-corrosive Paint

बà¥à¤®à¥à¤¬à¥ बà¥à¤°à¥à¤¡ मशà¥à¤¨à¥à¤ Trade Information

- Minimum Order Quantity

- 1 टुकड़ा

- डिलीवरी का समय

- 15-20 दिन

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About बà¥à¤®à¥à¤¬à¥ बà¥à¤°à¥à¤¡ मशà¥à¤¨à¥à¤

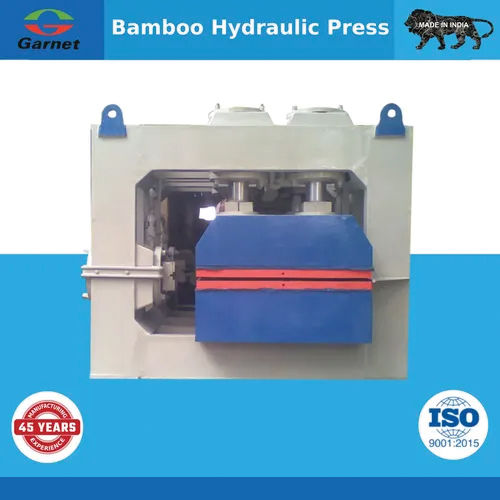

Buy Online the Bamboo Board Machine-a meritorious innovation spotlighted for its inestimable performance and virtuoso engineering. This semi-automatic, horizontal board-making machine processes natural bamboo strips into durable boards (2440 x 1220 mm) at a reduced price. With its heavy-duty gearbox drive, variable speed, and PLC-based control panel, it handles panel thickness from 10 to 50 mm and a capacity of 2000-3000 Kg/Day. The anti-corrosive finish, integrated water cooling, and 80 dB noise level ensure longevity and operator comfort. Perfect for exporters, manufacturers, suppliers, and wholesalers across India.

Versatile Commercial Applications of Bamboo Board Machines

Bamboo Board Machines are engineered for extensive commercial uses, supporting the manufacture of furniture, construction elements, and decorative panels. Their robust design enables effective usage across various surfaces such as woodwork, architectural structures, and customized decor. Highly suitable for large-scale operations, these machines are ideal in industrial workshops aiming for volume production as well as in specialty crafts, providing flexibility and reliability in every usage type.

Sample Policy and Market Accessibility

Exchanging sample Bamboo Board Machines is seamless, with samples available on request. A nominal asking price or outlay may apply, depending on the scope and specific requirements. The main domestic market served includes all regions of India, ensuring easy reach for manufacturers and commercial entities looking to invest in advanced board-making solutions. This policy underscores our commitment to transparency and customer-centric service.

Versatile Commercial Applications of Bamboo Board Machines

Bamboo Board Machines are engineered for extensive commercial uses, supporting the manufacture of furniture, construction elements, and decorative panels. Their robust design enables effective usage across various surfaces such as woodwork, architectural structures, and customized decor. Highly suitable for large-scale operations, these machines are ideal in industrial workshops aiming for volume production as well as in specialty crafts, providing flexibility and reliability in every usage type.

Sample Policy and Market Accessibility

Exchanging sample Bamboo Board Machines is seamless, with samples available on request. A nominal asking price or outlay may apply, depending on the scope and specific requirements. The main domestic market served includes all regions of India, ensuring easy reach for manufacturers and commercial entities looking to invest in advanced board-making solutions. This policy underscores our commitment to transparency and customer-centric service.

FAQ's of Bamboo Board Machines:

Q: How does the PLC-based control system enhance machine operation?

A: The PLC-based control panel automates essential processes, enabling intuitive operation, precise adjustments, and real-time monitoring, which enhances productivity and reduces operational errors.Q: What raw materials can be used with this bamboo board machine?

A: This machine is specifically designed to process natural bamboo strips, making it optimal for applications in eco-friendly board production and sustainable manufacturing.Q: When is the best time to carry out routine maintenance on the machine?

A: It is recommended to perform routine maintenance after every significant production cycle or as advised in the user manual, ensuring optimal performance and extended machine life.Q: Where can this machine's output boards be used?

A: The output boards, sized 2440 x 1220 mm, can be used in various industries including furniture, construction, and decorative panel manufacturing due to their versatility and durability.Q: What are the benefits of the integrated water cooling and anti-corrosive surface treatment?

A: The integrated water cooling system maintains ideal operating temperatures, preventing overheating, while the anti-corrosive paint ensures long-lasting machine durability, even in demanding environments.Q: How is the speed of the Bamboo Board Machine regulated?

A: The machine features a variable speed drive system controlled by the user, allowing precise adaptation to specific production requirements, enhancing efficiency and customizing output quality.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in तैयारशुदा परियोजनाएँ Category

बाँस की हस्तकला मशीनें

प्रॉडक्ट टाइप : अन्य, बाँस की हस्तशिल्प मशीनें

माप की इकाई : यूनिट/यूनिट

मूल्य की इकाई : Unit/Units

न्यूनतम आदेश मात्रा : 1

मूल्य या मूल्य सीमा : आईएनआर

वोल्टेज : वोल्ट (v)

लकड़ी या बांस बोर्ड बनाने की मशीन

प्रॉडक्ट टाइप : अन्य, लकड़ी या बांस बोर्ड बनाने की मशीन

माप की इकाई : टुकड़ा/टुकड़े

मूल्य की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 1

मूल्य या मूल्य सीमा : आईएनआर